What it’s like inside TVS' high-tech Hosur factory

Helping to feed India’s insatiable appetite for motorcycles is the TVS factory in Hosur - here’s what it’s like inside.

Call me close-minded, but I had an outdated idea of what the TVS factory in Hosur would be like. I pictured something less efficient, noisier and a lot more chaotic. But from the first moment I stepped into the factory gate, those expectations were blown right out of the water.

We were there for a few reasons. The first was to visit the factory and inspect some new models ahead of TVS’ entry into the UK and European markets. The other reason was to test some of the bikes we expect TVS to bring over.

The first day, though, was all about taking in the factory, and there is a hell of a lot to take in.

TVS - a short history of the brand and some key specs

TVS was founded in 1911, by T. V. Sundram (hence ‘TVS’) and is based in Hosur, in the state of Tamil Nadu. Hosur is an industrial hub, with Ashok Layland, General Electric and the truck maker Tatra, among others, all having facilities in the region.

TVS produced its first motorcycles in the late 1970s, and now boasts more than 5,000 dealers in India, five factories globally, and bikes (as well as three-wheelers) finding their way into more than 90 countries. The 28 assembly lines TVS owns globally can produce up to 1,000 bikes per hour and around 4 million bikes a year. The brand is now ranked as the third largest powered two-wheeler maker in India.

Today, the TVS plant in Hosur sits on the same site it has operated from since its foundation as a manufacturer. A sprawling site that has entrances in two provinces, multiple manufacturing buildings and even its own TVS Eco Park. It draws vast amounts of its power from renewable sources, employs three per cent differently abled workers, and has a 20 per cent female workforce. It’s also been voted one of the best companies for female workers in India.

What life is like at the TVS factory

We arrive at the factory around an hour after leaving our hotel in central Bengaluru. Having covered just 15 miles on the commute to ‘work,’ the time it’s taken helps to drive home just how important motorcycles are to the people of India.

The timing of our arrival coincides with the changing of the shifts, and we are greeted by a seemingly never-ending stream of workers exiting the plant, which is met by another influx of workers heading in to start their day. It’s busy, but not rushed, with security guards on the gates holding traffic and managing the throng of people.

After a lengthy press conference, which consists of lots of slides and numerous complicated flow-charts, we head into the facility to be greeted by a line of some of TVS’ most popular models. Tucked away within the lineup are the three bikes TVS builds for BMW: the G 310 RR, G 310 R and G 310 GS.

It’s not long after entering that we see the first proper production line, although this isn’t like any line I’ve seen. It’s worth noting that I’ve been inside big manufacturing plants before. A number of my family members worked in Peugeot’s Ryton plant in Coventry, and on more than one occasion, I had the chance to take a tour of that facility - albeit some years ago now. More recently, I’ve been on tours of the Triumph factory in Hinckley, both at the height of its UK manufacturing and in more recent years when it served as the Triumph Factory Custom (TFC) production base.

The TVS factory is, in many ways, nothing like either of those. For starters, some of the production lines don’t actually seem to have a fixed line on the floor of the building. Instead, automated robots piggyback the bike from one station to the next. Like some carefully choreographed ballet, as one worker finishes their task, be it hanging a rearset or attaching the brake calipers, the bike crawls its way forward to be taken closer to completion.

For a plant that produces so many bikes (nearly 30 a minute), it all seems very chilled out and calm. There’s no stressing about getting the job finished, and once the staff member has completed the job, it seems as though there is a bit of time to reset and focus on the next task.

And it’s not just the production line that gets the automated treatment. The factory floor is buzzing with autonomous creatures. One carried freshly powder-coated Apache RR and RTR 310 frames to the start of the line, and as this 20-strong group of journalists wandered aimlessly around the factory, the machine dutifully halted their journey and waited for a clear path before continuing on its journey.

Norton easter eggs on display

We then land at one of the most interesting parts of the factory, the engine building section. It’s a kind factory within a factory. Hemetically sealed with airlock doors and a special sticky door mat to prevent outside contaminants from entering the area. It was here that we saw numerous mid- and small-capacity engines being built, although it was three engines sitting alone on a bench that piqued my interest the most.

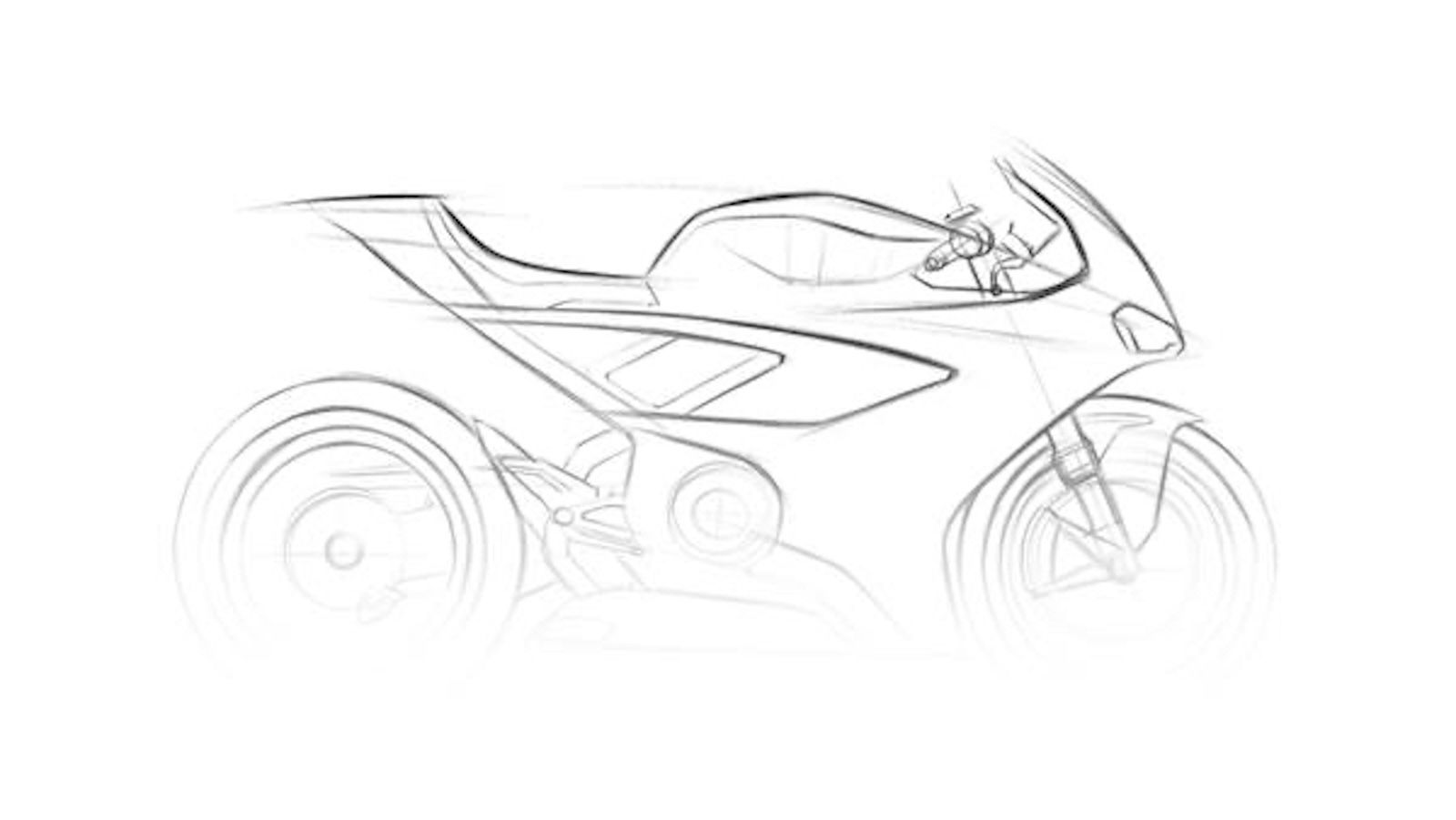

The aforementioned 310 models (above) are the largest capacity bikes in the TVS-built range. The 312.2cc single-cylinder engine powers the BMW-badged bikes, as well as TVS’ much-loved Apache 310 range. So, then, why am I standing staring at a V4 engine with “1200 cm3” cast onto the barrel? All signs point to this being the TVS-era Norton V4, the same engine that we expect to be landing in the recently teased V4 sports bike - estimated to be getting revealed at EICMA.

It’s not an identical-looking engine to the one we saw in the teaser images from Norton. That unit had polished aluminium engine covers, and this example featured casings topped off with gold powder-coated covers. This could point to TVS using another iteration of the engines in its own models, or it could just be TVS trying to throw us off the scent. Whatever the case may be, this wasn’t just left in full view by mistake - everything happens for a reason!

And it’s not just the V4 TVS held under our noses, as sitting alongside it were two more parallel twins, one which looked to be around 700 to 900cc, and another that could be related to the 450cc parallel twin-cylinder that is set to power the incoming BMW F 450 GS.

The idea that we’d just seen the new BMW 450 engine was further cemented as we travelled back from the factory tour. As our golf carts trundled around the site, a mid-capacity adventure bike with a parallel twin-cylinder engine was wheeled past us, covered by a sheet with its engine running. The exhaust end-can on that bike was identical to the exhaust seen in the patent images of the BMW F 450 GS. Again, that can’t just be a coincidence.

More than just a manufacturing facility

I mentioned before that Hosur is a plant powered by renewable energy and touted as one of the best to work at for female and differently abled workers, but really, that is just scratching the surface.

Aside from those very notable points, the TVS facility has another jewel in its crown: the TVS Eco Park. Set in the grounds of the factory, away from the hustle and bustle of the production lines and autonomous machines, sits a tranquil oasis of water, trees, rare plants and lots of wildlife.

At the heart of the park are a series of lakes and ponds, which are said to be in the region of 4 acres in size. These are all fed via the roof of the factory, which captures rainwater and sends it to pools.

Formerly just barren land, TVS has created a haven for wildlife and plants. Years after its completion, it’s now thriving, and it attracts birds and wildlife to the area that haven’t been seen for years. We spent around an hour wandering around the place and saw a cauldron of ginormous fruit bats (yes, I had to Google that collective noun!), Painted Storks, Egrets, huge Swallowtail butterflies, and more insects and invertebrates than you could shake an antennae at. And that is just what we actually managed to see. The area is home to more than 120 bird species, nearly 20 kinds of snake, 15 lizard species and more than 10 different kinds of amphibian. To truly take in the scale of what’s been done here, you’d ideally need to stay the night.

And this isn’t just a case of ‘plant the trees and build the ponds and then forget about it.’ TVS has invested big money in this 50-acre corner of its 320-acre site. The company, which, let’s not forget, builds bikes and three-wheelers as its core business, has employed a small army of people to tend the flowers and track the wildlife. From gardeners and groundskeepers to biologists and ornithologists, the staff list at the Eco Park reads more like a zoo than a motorcycle factory.

Final thoughts: If you look after your workers, your workers will look after you

One of the key takeaways I’ve got from spending some time at Hosur is how well the workers on the factory floor are treated. TVS claims to pay slightly above the going rate to staff at its sites, but just paying them a fair wage is half the story.

To help the staff get to and from work, TVS lays on complimentary buses for all its workers, which pick up one shift as it drops off another. As my morning commute to the factory proved, getting around Bengaluru is hard at the best of times. Taking that journey on for its staff not only makes the day less stressful for those commuting in, but ensures they arrive at work in a timely manner, fresh and ready to take on their shift.

The staff have access to green spaces, inside and outdoor areas when on breaks, as well as access to the Eco Park if they want it. They get two meals a day while on shift at the plant, completely free of charge - these things aren’t the norm in most industrial plants in India or around the world.

And it seems that this worker-first mindset is paying off, as from reading firsthand employee reviews from people who have worked or are still working at TVS, the overall consensus is that it’s a good place to work. Employee engagement is high, and many current employees talk about there being a good camaraderie between workers. And you can see that when you walk in the gates.

TVS’ Hosur facility is more than just a production powerhouse; it’s a reflection of how modern motorcycle manufacturing can coexist with sustainability and social responsibility. From the precision production lines to the serenity of its Eco Park, the plant feels less like a factory and more like a living, breathing ecosystem where technology, people and nature are all given equal weight.

It’s easy to see how this approach has helped TVS build a reputation that stretches far beyond India’s borders. With expansion into Europe on the horizon, the partnership with BMW and ownership of Norton already bearing fruit, Hosur stands as both a symbol of what TVS has achieved and a hint at where it’s heading next. If the spirit of this factory is anything to go by, the future of TVS looks every bit as polished, progressive and quietly confident as the bikes rolling off its lines.

Find the latest motorcycle news on Visordown.com.