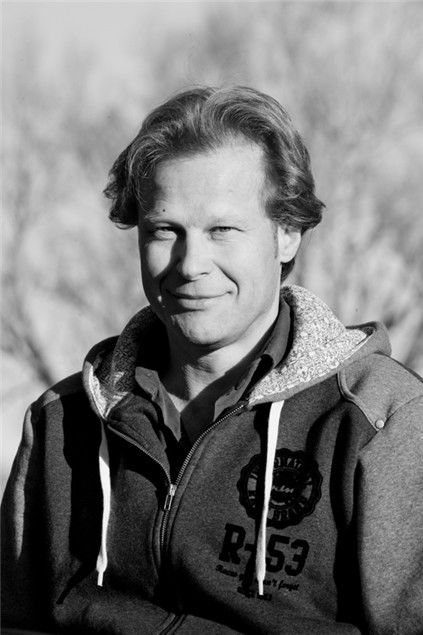

Manager of the KTM RC8 Department: Wolfgang Felber

“The story began in 2002, that was the time we had finished the Adventure and we thought about other ideas to use the V-twin engine. We outsourced it to Kiska to make a prototype, in late 2002 the first prototype was finished and it was rideable. I believe it still exists. The second bike was the show model. I have wanted to make the RC8 since I started at KTM. I approached the board with the idea in 2002 and asked for some small extra budget for a prototype, they said make it!

“The story began in 2002, that was the time we had finished the Adventure and we thought about other ideas to use the V-twin engine. We outsourced it to Kiska to make a prototype, in late 2002 the first prototype was finished and it was rideable. I believe it still exists. The second bike was the show model. I have wanted to make the RC8 since I started at KTM. I approached the board with the idea in 2002 and asked for some small extra budget for a prototype, they said make it!

We stuck with the trellis frame because it is the lightest design and it is very good for getting heat away from an engine, tube spar frames can act like a cover, it is also very easy to adjust the stiffness. We have a lot of GP experience on how important frame stiffness is. It should be stiff in tortional direction, but sideways very soft. We have learnt a lot from racing, physics is always the same, it doesn’t matter if it is four or two-stroke, 125 or 1,200cc.

Developing a new bike is hard work, but I reckon we lost 25% of the time just getting the bike through emissions testing. But we have to fulfill the rules, and we have done well. The race exhaust doesn’t make much difference, power and torque is almost the same, but the race silencer is 8kg lighter. Which is why we used an under engine exhaust, it dramatically improves the bikes handling. Imagine having the weight of your wife on the back, you ride like a drunken man, putting the exhaust under the engine is much better.

We invested a lot of time making the bike clean, if you look at it you can’t see many wires, cables, or tubes and the cockpit is clean. We wanted to have a bike that is very easy for maintenance, we have to do it ourselves and don’t want to waste our time! I’m a perfectionist, possibly too much sometimes. We know from off-road and GP racing how important it is to get a bike ergonomically right for a rider. A bike should fit like a hand made suit, not one from a shop. A factory rider gets a bike that fits him, and your weight influences the dynamics of a bike so much, so why shouldn’t a road rider have the opportunity of getting their body in the right position. Our aim is to give a rider a bike where everything just works, you can have your full concentration on the road or track.

If you have a bike that has a hard clutch, brake, horrible throttle response you will lose concentration. The RC8 is very rider friendly, which is why it has just 155bhp. Possibly this is wrong, some customers just read spec sheets, but we have made a bike with excellent gas flow at lower rpm for a very smooth throttle response. The torque curve is very flat, it makes the bike’s engine easy to control. I think ‘only’ 155bhp is not really a disadvantage, we learnt power isn’t everything with our MotoGP project. Maybe we go the wrong way, some customers think a bike with 180bhp must be faster than one with 155bhp, but if you look behind the curtain at the data recording you will find it isn’t always the case.”