BMW World Superbike team utilise 3D printing at the track

BMW has used 3D printing to make parts for the S 1000 RR to be tested prior to going into manufacture

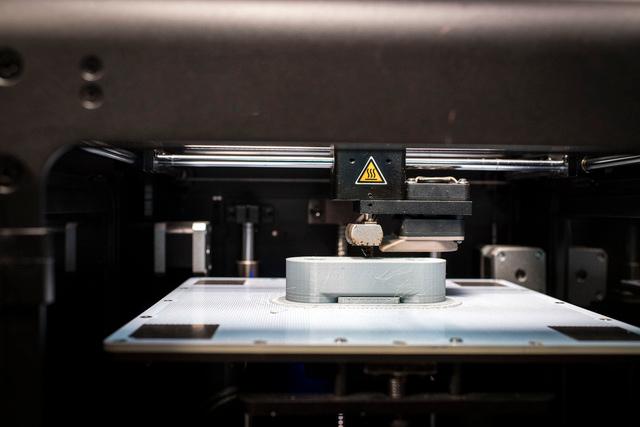

BMW has been using 3D printing while at the track to help speed up the development of its S 1000 RR World Superbike motorcycles.

3D printing and motorcycle manufacturing have been bedfellows for some time now. The rate at which items can be created with a CAD program and then prototyped makes using the system a no-brainer for teams in elite racing - although it is normally restricted to the R&D department, not the racetrack.

BMW S 1000 RR video review

BMW though has begun using the pits and paddock as another R&D department, as it has mobilised its designers and 3D printers, and is now prototyping and testing parts created on a printer during race weekends.

When designing a component under normal conditions, the new part is simulated on computers and then manufactured in metal or carbon before being installed on the bike. The 3D printing capability makes it possible to develop and test new components during race operations, thanks to greatly reduced production times when compared to traditional prototyping processes.

The team put the system to use at the recent WorldSBK double-header at Jerez and Portimão. The team needed to alter the rear shock absorber linkage for the demands of the undulating Algarve circuit. A prototype of the 3D-printed part was installed and tested. The final data was then sent to the supplier, who then used the data to manufacture a new linkage system between the race days. A few days later, in time for the start of the next race weekend at Portimão, it was available for installation on the BMW S 1000 RR.

How long before we start seeing this kind of tech in the MotoGP paddock!?