How Brembo's top-spec superbike brakes have changed since 1988

This weekend, the World Superbike racing circus is in Spain, racing at MotorLand Aragon. And, as it happens, it's thirty years since the first WSB race, at Donington Park here in Blighty, on April 3 1988.

Brembo's played a massive part in WSB (or WorldSBK as it's now dubbed) – 27 of the 30 rider titles have been won using its brakes. So, the Italian firm's taken a bit of a look at how its components have evolved since then. And since WSB is the premier production-based race class, and banned carbon brake systems in 1994, it's probably had the most impact on the stoppers we get on our road bikes.

The bikes were very different back in '88 of course. The top machines were legendary models like Honda's RC30 and Suzuki's GSX-R750 (Yamaha's OW01 would come a year later), as well as esoterica like Ducati's 851 and Bimota's YB4, and some of them came with Brembo brakes in stock form too. But for racing, the teams fitted the best kit from the time – meaning cast iron discs, two-piece aluminium calipers, conventional cast alloy master cylinders and a choice of organic or sintered brake pad materials.

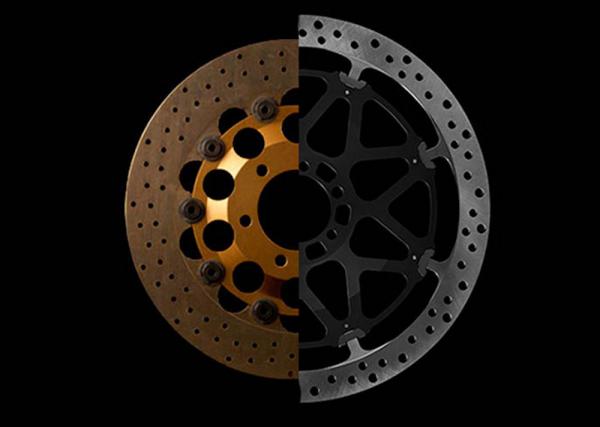

The discs were smaller than we're used to now – but otherwise they wouldn't look so out of place these days. Brembo had a choice of 290mm or 320mm diameter cast iron discs in 1988, depending on conditions and venue. Nowadays, the discs are stainless steel, and come in a choice of 328mm or 336mm sizes.

The calipers are probably the biggest visual change. Thirty years ago, Brembo Goldline units were state of the art, their two-piece radial-mount design seemingly all you could ever need. But there's been two major changes in architecture – firstly, the move to a billet, one-piece design, which cuts the flex and weaknesses of a two-piece caliper. The old calipers were bolted together, so the different thermal expansion rates of the steel bolts and the aluminium main structure also caused problems. Making a caliper from one piece is much more difficult of course – you can't just machine the piston cylinders with a big old drill from above into each half – you need to use a more complex milling process to come in from the edge and machine out the piston pockets from the disc side.

Secondly, and more straightforward, is the move to radially-mounted calipers. Bolting the caliper to the fork leg at both ends is a much better mechanical solution than mounting at just one end, with the other end hanging free, and makes for a much stiffer structure all round. It also means the mount bolts are fitted in tension rather than shear – the force from the caliper is 'pushing' into the fork with the bolt, rather than trying to bend across the width of the bolt as in an old-school axial mount. If you look from the side, and imagine how the caliper will try to move when the brake is applied, you can see how it will be trying to distort the bolt in each case. So radial caliper mounting means less stress on the bolts, so they can be thinner/lighter for the same strength and stiffness.

So, bigger discs, and stiffer, lighter, more efficient calipers and mountings. What else is there? Well, pad material for one – in 1988 many riders were using organic materials, which worked immediately from cold and were better in the rain. Sintered metal pads were a newer technology and while offering better performance ultimately, weren't so good in the rain and needed warmed up for full power. The organic pads wore out quickly and suffered glazing at high temperatures though, so sintered pads were the way forward, and 30 years of development means todays metal pads work well in the rain, and in wider temperature ranges too. Brembo's top spec WSB pad is the Z04 racing, and if you're feeling saucy, have a look at the cost of a set for your bike (£150 per caliper is a decent price…)

The last technology change has been to master cylinders. Old-style units used a piston which ran parallel to the handlebars, so when you pulled the brake lever, it operated through an angle, directing your hand's force sideways to push the piston along the cylinder and pressurise the brake fluid. Now, Brembo uses radial pumps, where the piston and cylinder are mounted perpendicular to the bars. That means, as you pull back on the lever, the force is channeled in the same direction, giving a more direct action from your hand to the brake fluid. Again, like the radial caliper mount, it's a simple enough change, and doesn't need a massive amount more in terms of engineering - although the high end ones are now machined from billet rather than cast, so are stiffer and stronger in the material sense too. But it's another load of improvements to the overall braking performance picture.

Those are the major tech changes – other improvements to stuff like brake fluid, hoses and the like will also play their part. Far bigger improvements to braking will also come from the bigger picture too – the WSB bikes of today are around 10-20kg lighter than the old beasties, and modern Pirelli WSB tyres are simply in a different dimension from the slicks of 1988. Better suspension and chassis designs will also play a part in making bikes easier to stop, although the extra 80-100bhp might be working against us here...

As a result of all that, Brembo reckons the braking distances for bikes like Chaz Davies' Aruba.it factory Ducati Panigale R are now about 25 per cent shorter than back in the early days of Davide Tardozzi, Joey Dunlop, Marco Lucchinelli and Fred Merkel. Impressive stuff!